Elektron® WE43B

Elektron® WE43B is a high strength magnesium based casting alloy developed and patented by Luxfer MEL Technologies for use at temperatures up to 300˚C.

This alloy system maintains its good mechanical properties at elevated temperatures, without the use of either silver or thorium. The alloy is stable for long term exposure up to 250˚C. Elektron® WE43B has excellent corrosion resistance characteristics.

The excellent retention of properties at elevated temperatures will be of interest to designers of aeroengines and other power systems, helicopter transmissions, missiles, racing and high performance cars.

UNS No. M18430

ASTM B80

AMS 4427

MAM 4427

AECMA MG-C96002

ISO 16220: MC95320

Yttrium: 3.7–4.3%

Rare earths: 2.4–4.4%

Zirconium: 0.4% min

Magnesium: Balance

The alloy develops its optimum properties in the fully heat treated condition ie:

- Solution heat treat for 8 hours at 525˚C

- Air cool, hot water or polymer quench

- Age for 16 hours at 250˚C, Air cool

Specific gravity: 1.84

Coefficient of thermal expansion: 26.7 x10-6K-1

Thermal conductivity: 51 Wm-1K-1

Specific heat: 966 Jkg-1K-1

Electrical resistivity: 148 nΩm

Modulus of elasticity: 45 x 103 MPa

Poissons ratio: 0.27

Melting range: 540–640˚C

Damping index: 0.09

Vickers hardness: 85–105

Minimum specification tensile properties:

0.2% proof stress: 172 MPa

Tensile strength: 220 MPa

Elongation: 2%

Castability

Fine grained and pressure tight with good casting characteristics.

Pattern makers shrinkage factor

1.5%

Weldability

Fully weldable by the tungsten arc inert gas (TIG) process, using filler rods of the parent alloy composition.

Machining

Elektron® WE43B castings, like all magnesium alloy castings, machine faster than any other metal. Providing the geometry of the part allows, the limiting factor is the power and speed of the machine rather than the quality of the tool material. The power required per cubic centimetre of metal removed varies from 9 to 14 watts per minute depending on the operation.

Surface treatment

Normal protective treatments apply for Elektron® WE43B but some chromating baths may need to be modified for the satisfactory treatment of castings. Please refer to Luxfer MEL Technologies Design Guide.

Corrosion resistance

ASTM B117 salt spray test

Corrosion rate: 0.1–0.2 mg/cm2/day

10 mpy

Typical tensile properties

0.2% proof stress: 185 MPa

Tensile strength: 265 MPa

Elongation: 7%

Typical compressive properties

0.2% proof stress: 187 MPa

Ultimate strength: 323 MPa

Typical shear properties

Ultimate stress: 160 MPa

Fracture toughness

KIC: 15.9 MPa m1/2

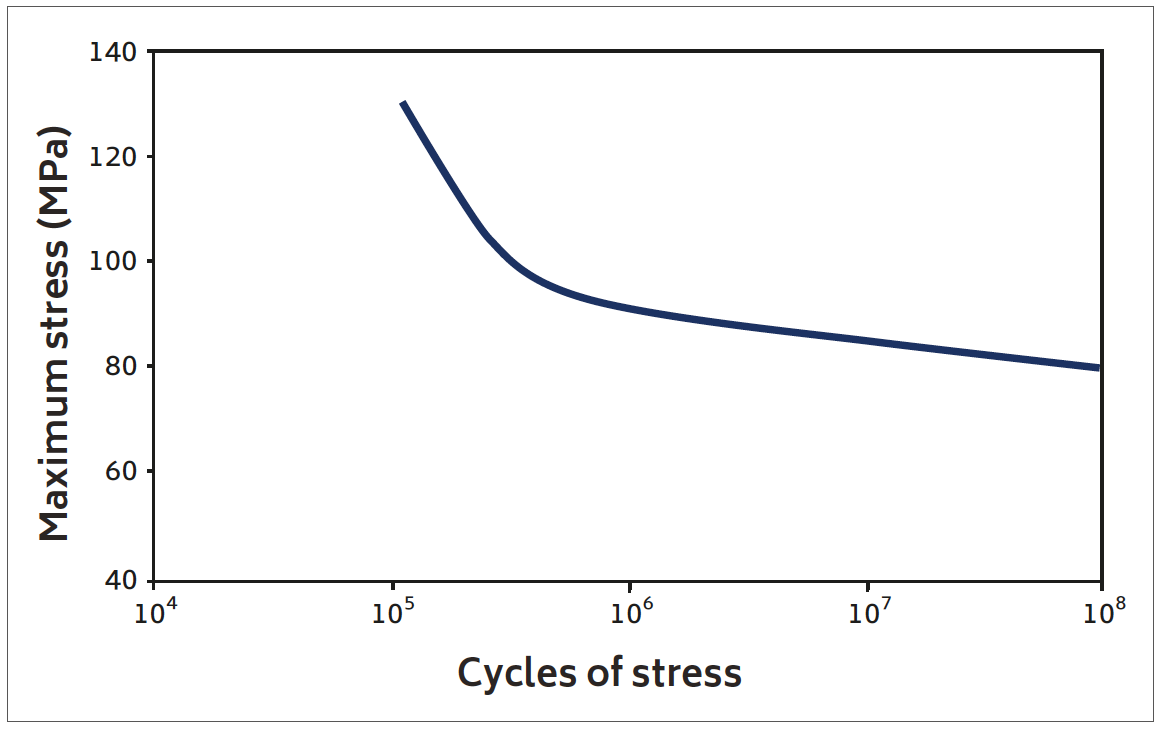

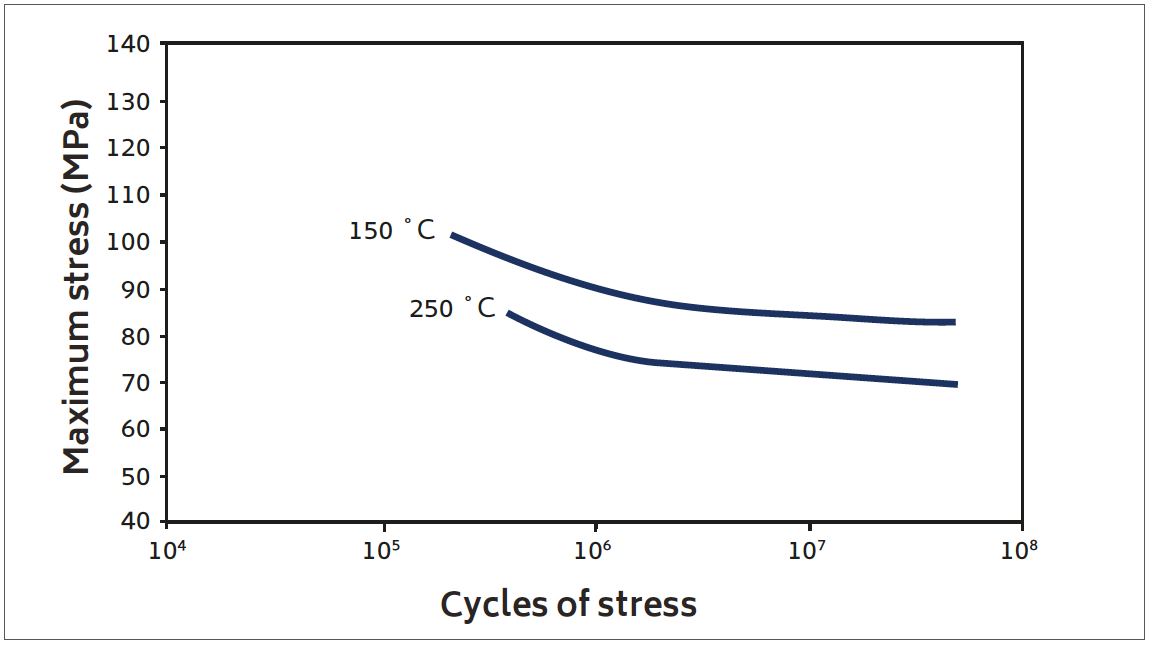

Fatigue properties

Figure 1. Rotating bend fatigue test.

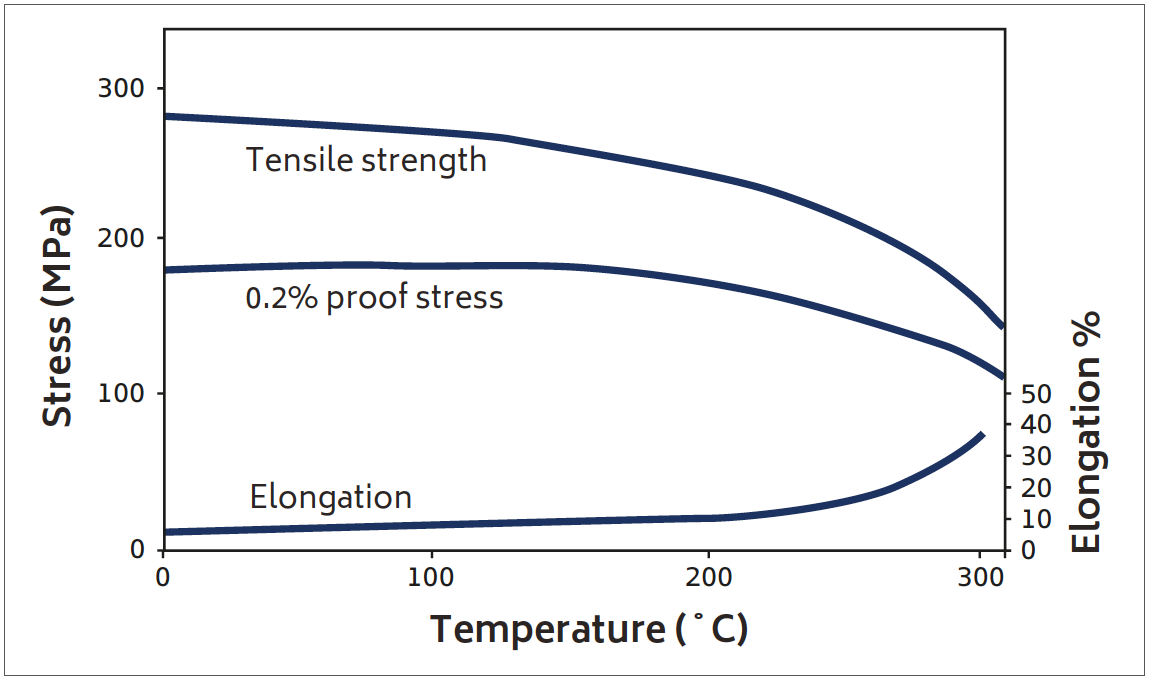

Typical tensile properties

Figure 2. Effect of temperature on tensile properties.

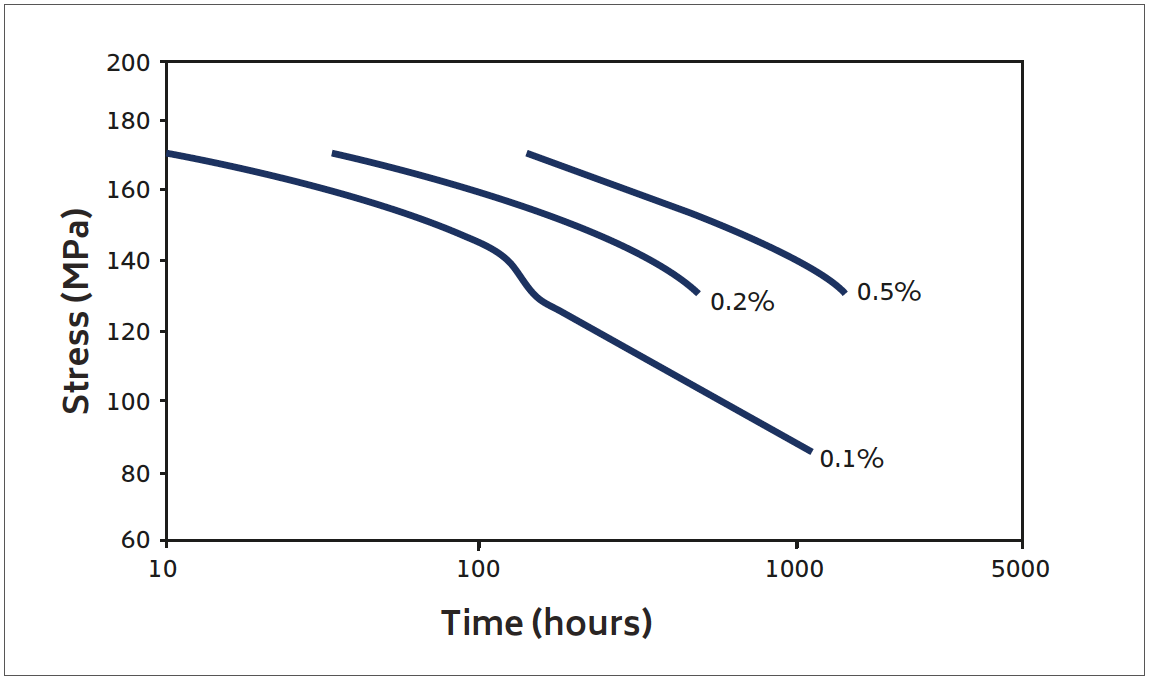

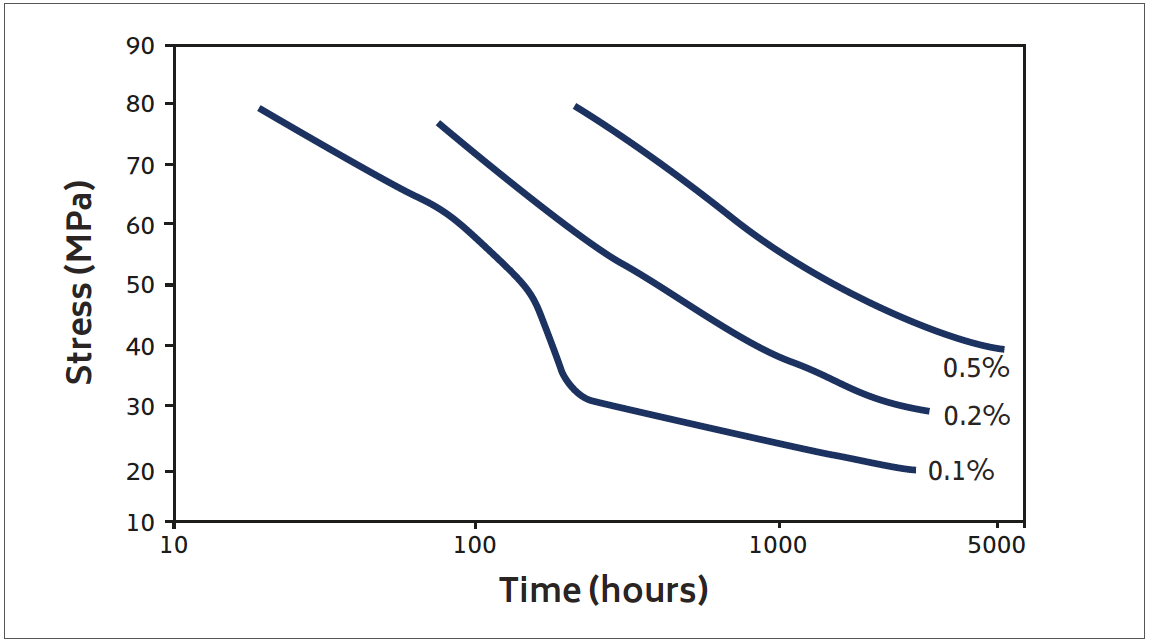

Creep properties

Figure 3. Stress / time relationship for specified creep strains at 200˚C.

Figure 3. Stress / time relationship for specified creep strains at 200˚C.

Fatigue properties

Figure 5. Rotating bend fatigue test.

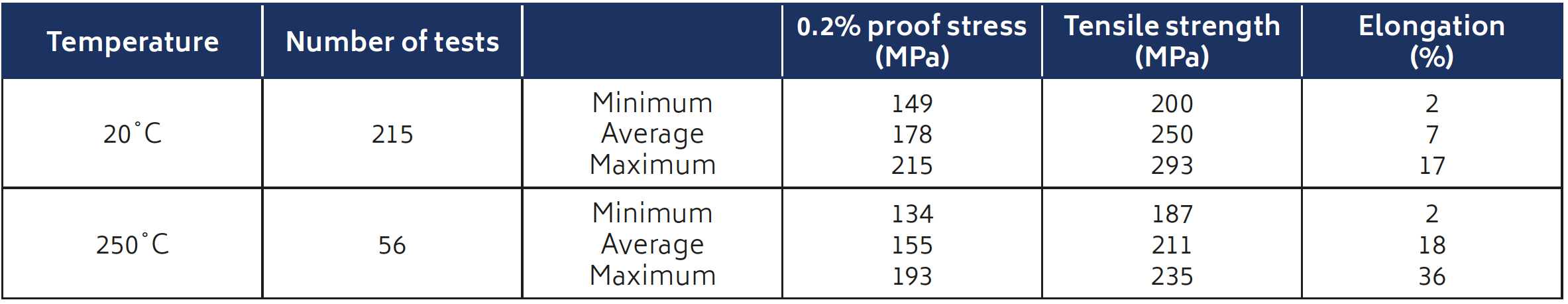

Table 1. Cut up properties on samples taken from actual castings.