Magnesium Extrusions Summary

A Summary ofLuxfer MEL Technologies Magnesium Extrusions Capabilities

Luxfer MEL Technologies is a world leader in the development and supply of high quality extruded products. These lightweight alloys are used as forging feedstock, as base material from which to machine components or as custom shapes to integrate directly into a component. Luxfer MEL Technologies operates two dedicated presses to supply a full range of extruded magnesium alloys and we continue to develop new alloys for future applications.

- Round bar

- Square/rectangular sections

- Hollow tubes/sections/custom profiles

- Multi-hollow sections/custom profiles

- Forging feedstock

- Machining feedstock

- Solid, hollow or multi-hollow custom

- Profile shapes

- Near net shapes

Where appropriate, alloys are also available heat treated.

- Elektron® 43, Elektron® 675

- Elektron® 21, Elektron® WE43, Elektron® WE54

- Elektron® RotaMag® AZ80A, AZ61A, AZM, AZ31B

- M1A, ZM21

- Pure Mg

- Custom alloys

- ASTM B107-13

- ASTM B91

- AMS 4352H

- AMS 4350M

- AMS 4485

- Customer defined specifications

Ultrasonic Inspection to AMS 2154 Class B, A, AA and AAA. Luxfer MEL Technologies has state of the art, custom built immersion ultrasonic testing equipment.

Lengths

25 mm to 6 m

1 inch to 20 ft

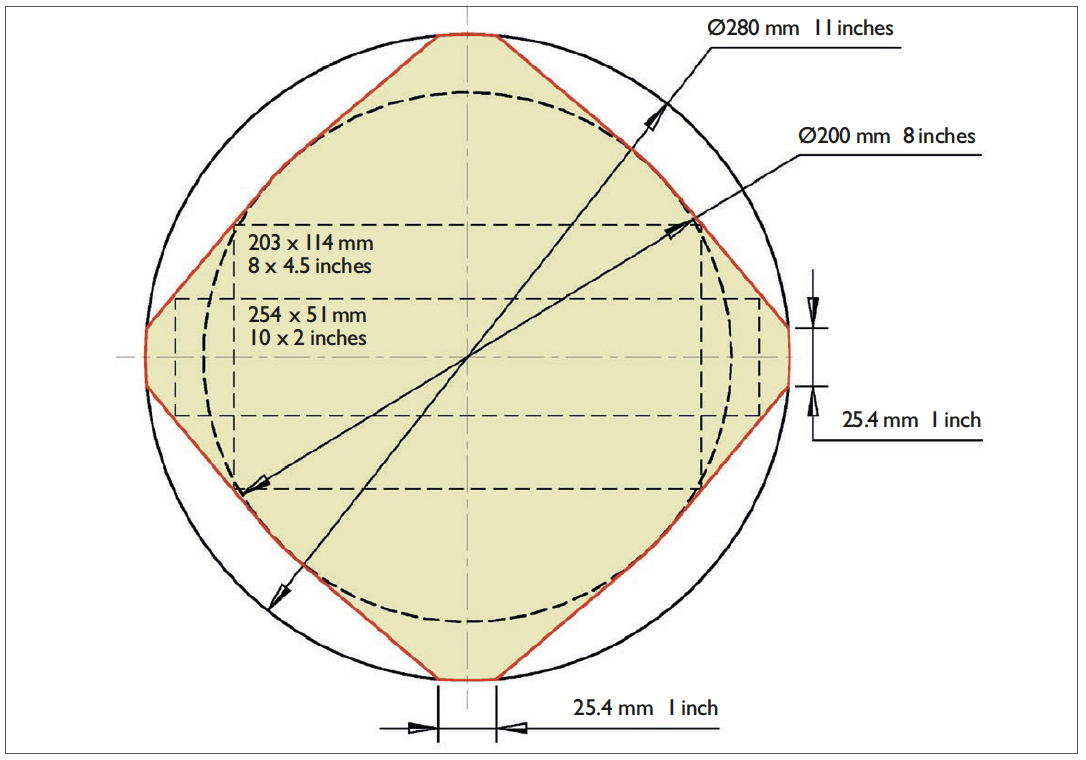

Square/Rectangular Sections

Thickness:

10 mm to 280 mm

3/8 inch to 11 inches

Width:

10 mm to 280 mm

3/8 inch to 11 inches

Thickness and width are inter-dependant. Please see Figure 1.

Figure 1. Extrusion press size capability.

Round Bar Diameters

1.6 mm to 200 mm

1/16 inch to 8 inches

Custom Profiles

Luxfer MEL Technologies manufactures complex solid and hollow profiles using the latest extrusion die technology within the scope of our size capability. Why not get in touch with us to discuss your exact requirements?

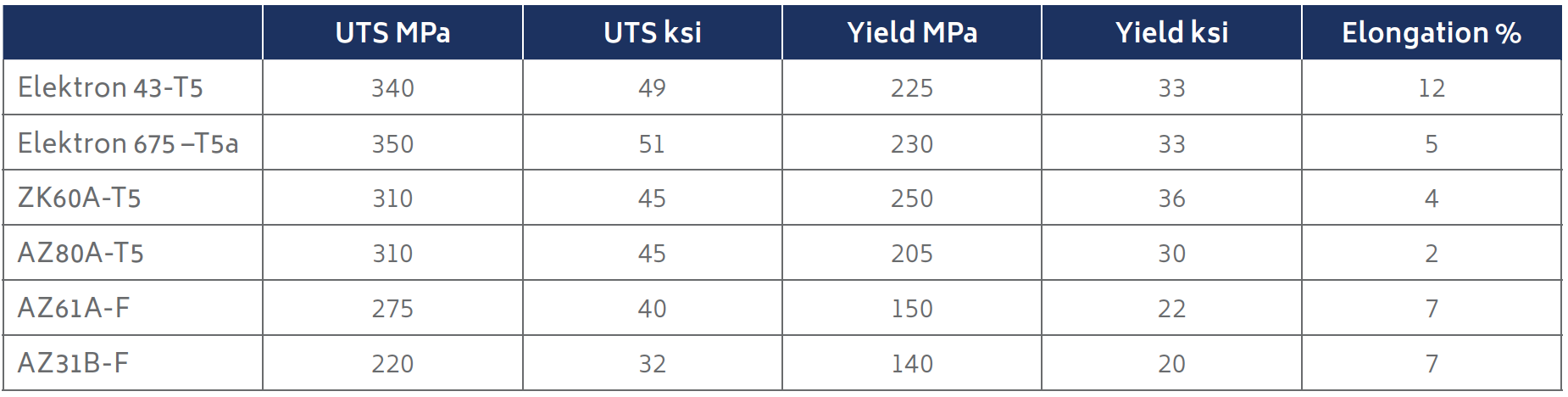

The minimum expected properties of common magnesium extrusion alloys are shown in the table below.

Table 1. ASTM B107-13 specification minimums for common magnesium extrusion alloys – solid extrusions.

Meet the Magnesium Extrusions Team & Get in Touch

Rick Tonge MBA

Product Line Manager

Europe, Middle East & Asia

Based in Manchester, UK, Rick supports our oilfield customers outside of North America. Partnering with our global customers, Rick enables his clients to design high performance products using Luxfer’s dissolving and non-dissolving material technology. Why not reach out to Rick today to discuss how Luxfer’s innovative material technology can work in your completion tools setup?