The Match Made in Heaven:

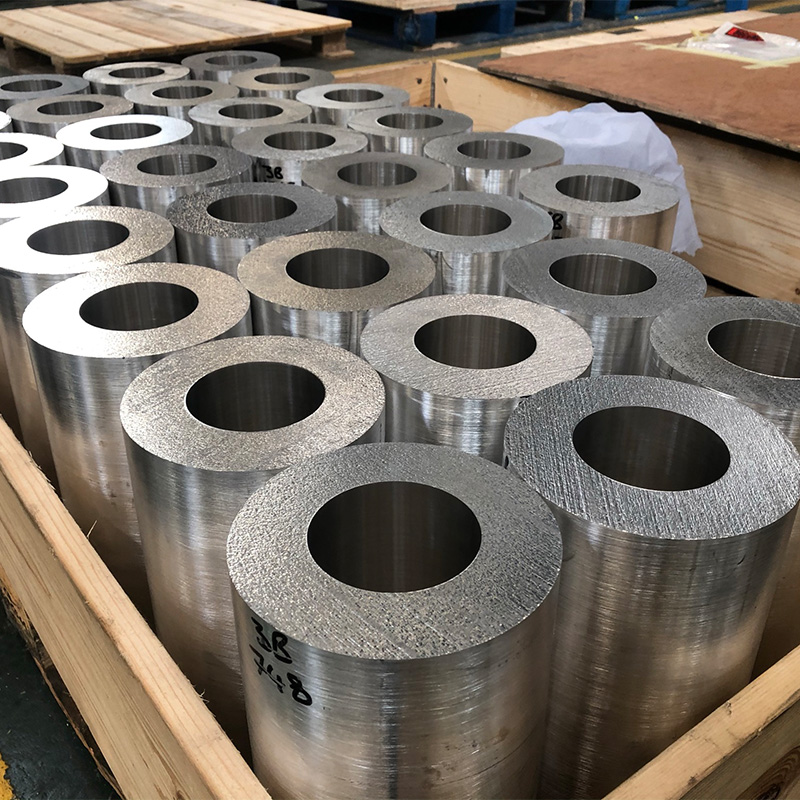

Luxfer MEL Technologies SoluMag® Seamless Tubes for Frac Plug Components

Experience the unparalleled performance of SoluMag® seamless tubes, meticulously designed for frac plug components. Our innovative SoluMag® products are available in both bar and seamless, extruded tube forms.

These exceptional tubes boast higher strength and impressive resistance to deformation and internal pressure, ensuring optimal performance even in the most demanding downhole environments during a typical frac operation.

Seamless tubes serve as the ultimate raw material for creating dissolvable frac plug components, thanks to their unique properties and versatility.

One of the standout benefits of SoluMag® seamless tubes is their adaptability in terms of customizable ODs and IDs. This flexibility in sizing options enables us to provide near net shapes tailored to individual frac plug components, ensuring a seamless fit for every application.

Moreover, SoluMag® seamless tubes are the go-to choice for plug components due to the consistent material properties present in every tube we produce, guaranteeing exceptional quality and reliability.

By choosing SoluMag® seamless extruded tubes for your components, you’ll reap the benefits of working with one of the lightest and most robust structural metal alloys available.

Machining SoluMag® offers numerous advantages, including:

- Energy efficiency: Requires only about 55% of the power needed for aluminum machining

- Speedy processing: Facilitates high cutting speeds, large feed rates, and greater depths of cut

- Well-broken chips: Results from the superior free-cutting qualities of SoluMag

- Prolonged tool life: Reduced tool wear ensures extended tool longevity

As part of our commitment to sustainability, Luxfer is proud to offer a drum pick-up and recycling service for your SoluMag chips.

Trust in SoluMag® seamless tubes for your frac plug components and experience the difference that quality, innovation, and precision can make.