What are the Properties of Magnesium Alloys?

Luxfer MEL Technologies Lightweight Magnesium Alloys Enable Lighter, Stronger and Safer High Performance Designs

Magnesium Alloys and their Properties

Magnesium alloys are a group of materials that consist mainly of magnesium (Mg) as the primary element. These alloys have a variety of properties that make them suitable for different applications.

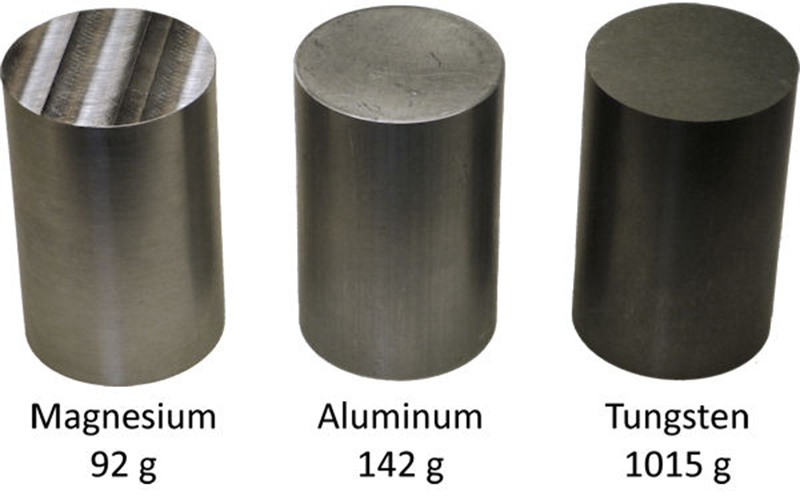

One of the key properties of magnesium alloys is their low density. Magnesium has a density of only 1.74 g/cm3, which is significantly lower than other metals such as aluminum (2.7 g/cm3) and steel (7.8 g/cm3). This low density makes magnesium alloys an attractive choice for applications where weight savings are important, such as in the aerospace and automotive industries.

Another important property of magnesium alloys is their high strength-to-weight ratio. Magnesium alloys can have tensile strengths that are comparable to other structural metals such as aluminum and steel, but with a much lower weight.

Machinability, Castability, and Corrosion Resistance

Magnesium alloys are known for their excellent machinability, allowing them to be easily cast, forged, and extruded. They can be welded and brazed without difficulty, and exhibit good corrosion resistance. Additionally, magnesium alloys possess remarkable damping properties, making them valuable for applications requiring vibration isolation and noise reduction.

Luxfer has a developed a range of unique magnesium alloys that further enhance the advantages of magnesium materials. Elektron® 43 alloy is a light, high strength wrought magnesium alloy for use at temperatures up to 250˚C. Designs in Elektron® 43 can be 20% to 30% lighter than a corresponding aluminium design. Elektron® 43 is available as rolled plate, forging feedstock and extruded bar, section and profile. Elektron® 43 is an optimised wrought evolution of the original casting alloy, Elektron® WE43.

The properties of Elektron® 43 mean it is well suited for use as feedstock material from which to machine high performance components, especially those associated with elevated temperature performance.

Conclusion

Magnesium alloys, with their low density and high strength-to-weight ratio, are a fascinating class of materials suitable for a wide range of applications, including aerospace, automotive, and electronics. Luxfer MEL Technologies’ Elektron® 43 alloy is a testament to the potential of magnesium alloys in helping to create a safer, cleaner and energy efficient world in various industries.

Discover how magnesium alloys can fit within your projects and get in touch with the team today.

Rick Tonge MBA

Product Line Manager

Europe, Middle East & Asia

Based in Manchester, UK, Rick supports our oilfield customers outside of North America. Partnering with our global customers, Rick enables his clients to design high performance products using Luxfer’s dissolving and non-dissolving material technology. Why not reach out to Rick today to discuss how Luxfer’s innovative material technology can work in your completion tools setup?